September 22, 2020

If your company is still sending and receiving documents to business partners by email or snail mail, you’re wasting a lot of time and hurting your supply chain efficiency. That means you’re also wasting money. Electronic data interchange (EDI) allows your company to exchange business documents computer-to-computer. The most common uses for EDI are purchase orders and invoices. But with supply chain, EDI is also commonly used for advanced ship notices, inventory documents, bills of lading, customs documents, and payment information.

EDI eliminates human involvement and the tedious, time-consuming steps of handling the documents, mailing, faxing or emailing them, and doing the same on the receiving end. EDI is not only paperless, it’s free of human intervention. While a lot of businesses exchange documents electronically, like sending a contract by email, EDI differentiates itself by isolating that to exchanges between computer systems. Humans may get involved to address errors, quality review or other situations, but the humans are not manually hitting “upload” or “send” as part of the process.

EDI is more than just electronic communication. It’s transferring structured data by agreed-upon standards. The businesses exchanging the information through the EDI format are called trading partners.

How EDI Works

Without getting into the nitty gritty, think about the manual process for sending an invoice. The accounts receivable person creates an invoice. The person converts it to a PDF and emails it to the client. Or the person prints it out, and sends it to through the company’s process to get stamped and mailed. The client receives the invoice, logs it into their system, forwards it to the appropriate person or department for approval, and at some point pays it. That takes a lot of time and there are multiple opportunities to lose the invoice or make errors.

With EDI, the invoice is converted automatically to a specified format and sent to the client. The information is transferred from the company’s computer to the client’s computer with no intermediate steps.

EDI Standards

The process of converting the information into a specified format involves EDI standards. The information must be sent with the same fields as the paper document would have, but every company has a different document format. What they have in common, however, are the types of fields used for each. That could include a billing address, shipping address, list of UPC product numbers, quantities, amounts, and dates. As long as the information being exchanged is put in a common format, it can be understood by both parties.

EDI uses standards to harness the process and so each side understands how to code or automatically interpret the shared information. Different standards can be based on location or industry, as industries have their own needs. For global supply chains, that format might be GS1 EDI. In the United States, companies might use ANSI ASC X12, common in North America, while UN/EDIFACT is an international shipping standard popular outside North America. Each EDI format has multiple versions, so the trading partners must agree to using the same version as well as the same format, much like computer operating systems and software programs have different programs and versions.

The standards include the optional and mandatory information to include from a document type, noting the document structure and rules. Think of the standards as building codes which must comply with certain rules. There are also specifications, which are like blueprints. Examples are using integers, decimals or date formats like mmddyyyy. If the specifications are intended as machine-readable instructions used in translation software, then the term “mapping” may be used.

It doesn’t matter what EDI format companies use, as long as they agree to use the same one with each other. That’s why standardized protocols emerged, so industries can share the same standards. Companies often use EDI translator software through a service provider or they have it in-house. This can translate the EDI format, making it easier to exchange information with numerous trading partners. It allows internal business applications to easily process the documents and information without needing a different EDI system for each trading partner.

Transmitting EDI

Formatting the information in a specific way is important, but they must also agree on a method to transmit it. They can send the information directly, or they can use an intermediary. The direct method is called point-to-point or direct connection, where the trading partners share information directly online, preferably with security protocols in place. If using an intermediary, the trading partners would use a third-party’s value-added network (VAN) to manage the data transmission. They might use a mail boxing paradigm. Here are some options for companies to transmit EDI information:

· HTTP

· FTP, SFTP and FTPS

· mModem (synchronous and asynchronous)

How EDI Helps Businesses

EDI helps companies improve efficiency, lower cost and reduce errors. It’s not hard to see how that happens. With paper-based systems, errors can be introduced at any step. A document can be delayed or lost. Human intervention is time-consuming, and again, error-prone. The mail service, especially during the COVID-19 pandemic, is slower than usual.

When document information is transferred, it arrives within seconds and it can be automatically routed to the proper place via the company’s order management system, allowing the trading partner to use that information immediately. Let’s break down some of the benefits.

Cost savings

Payment discounts: With a better understanding of payment dates and immediate receipt and logging of invoices, a business can understand their accounts payable situation. Payments can be negotiated to take advantage of discounts offered for early payment, and those can be scheduled through automated processes. Imagine the savings realized by taking advantage of even a 2% discount across multiple high-volume vendors.

Manual labor: Since EDI is automated, companies can use their staff for projects requiring brain work, not paper pushing. No more manual filing or printing or time spent searching for that document someone said they sent. Employees often don’t enjoy these parts of their jobs. They can be given more interesting assignments and feel valued.

Errors: How many errors does your company deal with because an order is misplaced or the information was improperly documented from a phone call? What about deciphering someone’s bad handwriting or the inability to read all of a fax because of poor quality transmission or a missing page?

Supplies: Converting to EDI means less paper, postage and storage for that paper. Expensive printer ink can be saved for something else, or phased out altogether.

Lower inventory levels: With faster order processing, companies can lower their inventory levels, improving cash management.

Efficiency and strategy

Transaction speed: Transactions can be accelerated with EDI, because there’s no data lag. An order comes in via EDI, it can be sent to a picker within minutes. There’s no waiting days to weeks for forms to arrive on paper.

Real-time tracking: Data is money in today’s fast environment. If you’re exchanging real-time data, it can be used to improve KPIs like cash flow, cycle time, and order-to-cash cycles.

Visibility: Visibility is one of the key strategic words for supply chain these days. EDI allows this visibility because the data is not trapped on paper or hidden during routing. It’s in the computer system and available for analysis at all times. Supply chain managers can better understand and respond to market demands, and use a demand-driven model or a just-in-time model.

Improved relationships: Some vendors or clients insist on EDI with business partners because they know what a difference it makes in their business. If you’re not using EDI, you are missing out on working with vendors who are likely offering a higher level of customer service and greater efficiency. With fewer errors on both sides from EDI, relationships with your business partners will improve.

Order improvement: Since orders can be tackled more quickly, there will be fewer cancelled orders as customers wait less time before receiving them. Your company has visibility into its stock, so you can ensure you have the ability to fill the orders on time.

Shortened lead time: With more efficient timing, companies can deliver new products more quickly and shorten the lead time for product changes.

Adding markets: With EDI, your company can more easily enter new markets, as onboarding is much simpler. And especially with foreign business partners, being able to send data electronically in a common format can save money and time.

How EDI fits into the integration landscape

EDI is not a new technology – it’s been around since the 1970s. EDI is just one piece of a supply chain integration to improve efficiency and reduce the costs of running a business. The EDI format should be chosen to integrate with a company’s business system. Depending on how automated the operations are, the company may need to retool some processes, like receiving invoices electronically instead of by mail.

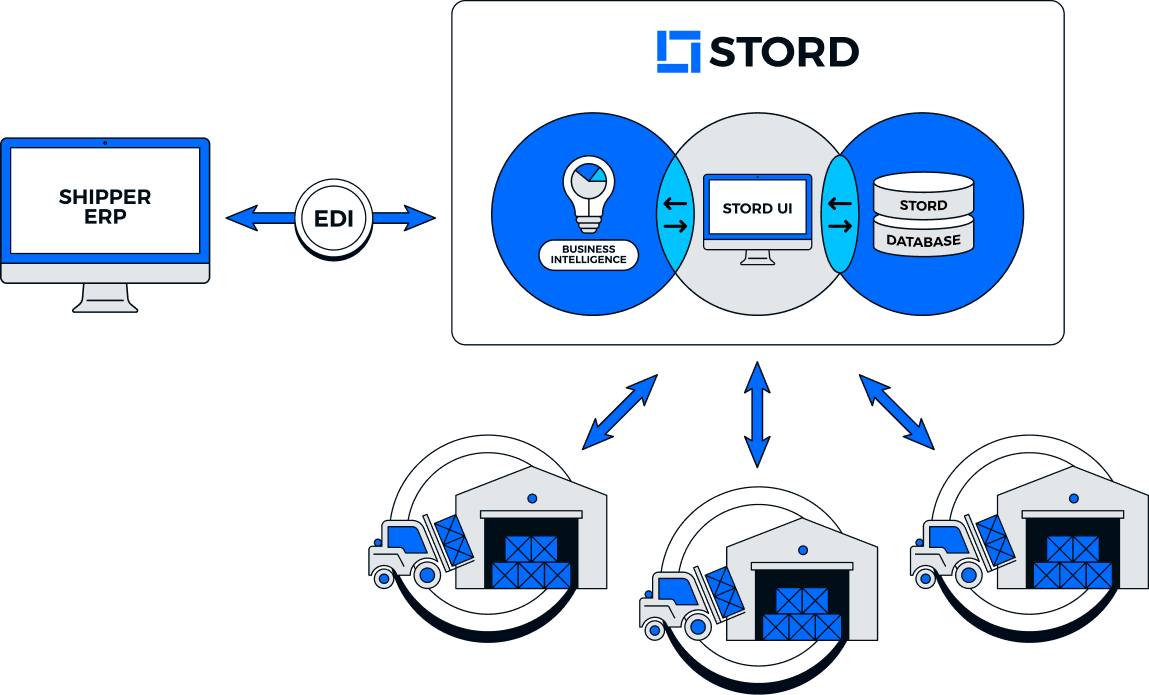

Automating the data exchange can positively impact the supply chain, through purchasing, order fulfillment, shipping confirmations, shipment scheduling, and tracking. This information can be shared between a fulfillment partner’s warehouse management system and the retailer’s order management system. The accounting information, like generating invoices and an audit trail, is helpful to integrate with a company’s finance system.

Stord’s bespoke software, which offers end-to-end visibility across all warehousing facilities and 3PLs in a company’s distribution network, also uses EDI connections to connect to a retailer’s platforms, making an unbroken chain for data to move. Talk to us about how we can help you improve your company’s efficiency and lower costs through solutions like these.