Supply chain technology used to rely on on-premise systems that were installed locally, able to conduct their own processes yet unable to share information with other systems. Now that more supply chains depend on network computing and the cloud, systems collaborate and exchange information, giving us access to a plethora of data from multiple parts of the supply chain to analyze.

Multiple types of analytics can be derived from these insights:

Descriptive analytics provide visibility into what’s happening in the supply chain, stating the facts of KPIs like delivery time or freight cost per unit.

Diagnostic analytics help you understand why something is happening. “What if” simulations can prevent a past problem from occurring again, or identify how to re-create a scenario that resulted in a benefit.

Predictive analytics show companies what the likely outcomes and business implications are of any given scenario. These analytics are especially helpful for risk management.

Prescriptive analytics take it a step further and tell you what you need to do in order to achieve your operational and financial supply chain goals.

47% of companies say their supply chain plans are inaccurate...

What’s the difference between predictive and prescriptive analytics?

Predictive analytics uses historical data to show you what will happen to X if Y happens. Prescriptive analytics uses historical data to show you how to manipulate Y to make X happen. 47% of companies say their supply chain plans are inaccurate¹ because supply chains are 1) complex, with many different parties and factors working together and 2) constantly reacting and adjusting to a fluctuating market. It’s a network of moving parts, so even if you know what will happen to X if Y happens, you don’t know how to view and control the effect that this scenario will have on Z. With large supply chains, even a small change, like a 1% increase in freight charges, can have a massive ripple effect that results in thousands of dollars in additional costs.

Benefits of Prescriptive Analytics to Supply Chain Planning

Demand Forecasting & Replenishment Planning

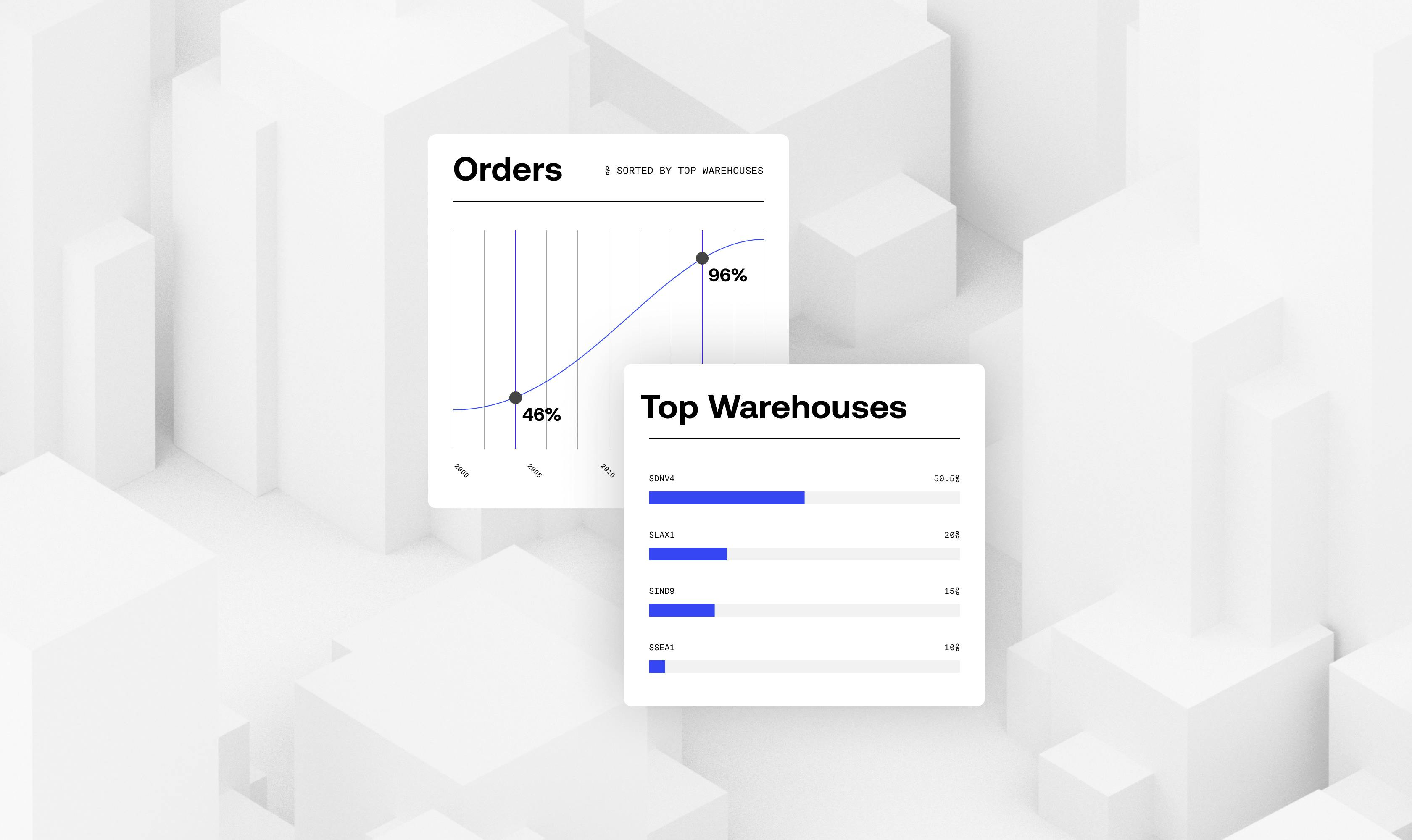

Use historical shipment and order data to determine where additional inventory needs to be stored in order to meet nearby customer demand and avoid stockouts. Identify each product’s seasonal and geographic trends and adjust available inventory levels accordingly, down to the individual retail store.

Procurement

Use pricing and profitability data to determine reasonable rates with your supplier, manufacturers and partners to ensure accurate billing and shorten negotiation times.

Freight Management

Run network optimization reports and pool distribution models to find redundant or missing transportation lanes. Track the costs of invoice audits, as well as the number of mistakes or unplanned accessorials, to find where you’re leaking money.

Benefits to Financial and Operational Metrics

Inventory Velocity

Quicken stock turns by using historical shipment data to store inventory closest to where demand is highest. Use past demand trends to determine how you want to target customers, and position those products in the forefront in stores and online.

Delivery Time

Position high-demand products closer to the customers buying them to shorten delivery time and improve customer satisfaction. Adjust freight lanes after a network analysis to determine where your high and low-demand lanes need to be.

Fill Rate

Using historical order data again, determine how much inventory you need to have in stock to meet your optimal fill rate, per each warehouse location. Use prescriptive analytics to take into account additional factors like seasonality, the freight market, and outstanding circumstances like COVID-19.

Gross Margin Return on Investment

Compile all supply chain financials and analyze current gross margin return on investment, and use prescriptive analytics to find the best course of action to achieve your goal GMROI. At the same time, evaluate the potential trade-offs to delivery time and customer service.

77% of shippers experience problems with the availability of clean data. And once they have it, only 26% of shippers report that they are satisfied with their existing analytics capabilities.

Where to Get Prescriptive Analytics for Your Supply Chain

Before you can get analytics, you need data. But clean, complete supply chain data isn’t easy to find and collect for every company: 77% of shippers experience problems with the availability of clean data². And once they have it, only 26% of shippers report that they are satisfied with their existing analytics capabilities².

Integrating the software systems of your freight and warehouse partners is key to total visibility into all of your supply chain data. Relying on spreadsheets sent over email or having to log into each WMS individually is time consuming and prone to human error, as well as data corruption. Integrations ensure that all supply chain information is sent directly to your ERP in real-time.

Third-party business intelligence tools can work with your company to take your data and perform analyses that show you what actions you need to take in order to achieve a desired goal. If you're wary of using just another optimization tool, consider using a supply chain partner like Stord, who has the tools to quickly execute recommendations. Our data science team can run the reports you need to optimize your supply chain, using the data collected in our cloud-based platform. Our supply chain team can then recommend where to make changes and help implement those changes with our network of warehouses and freight carriers.

Get Connected. Get Stord.

To learn how STORD can help optimize your distribution network, contact us at 1-866-502-9278 or visit stord.com/get-started.

¹Ventana Research. “Supply Chain Planning with Prescriptive Analytics,” 2018.

²CSCMP (2019). 2020 24th Annual 3PL Study [PowerPoint slides].